An Unbiased View of 24??media

An Unbiased View of 24??media

Blog Article

Examine This Report on 24??media

Table of Contents6 Easy Facts About 24??media ShownThe Single Strategy To Use For 24??mediaThe Best Guide To 24??mediaThe smart Trick of 24??media That Nobody is DiscussingNot known Details About 24??media

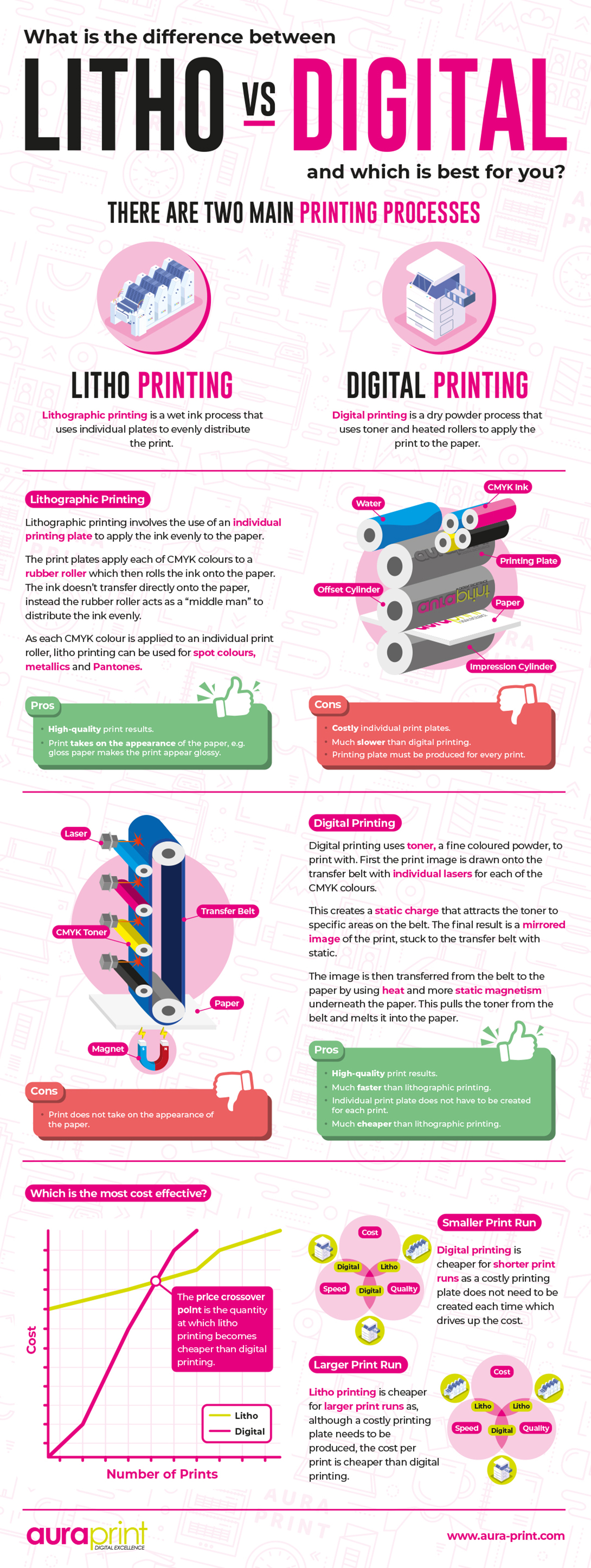

Advancements in print technology are changing the communications playing area when it comes to top quality, cost and cutting-edge capabilities. Countered printing and electronic printing are the significant procedures whereby print jobs are undertaken both making use of four-color printing methods. Each alternative has its benefits, offering different methods to satisfy the demands of diverse manufacturing jobs.

Commonly, this has been one of the most constant technique for exactly keeping color matches, making it excellent for print runs that just require fixed printing such as pre-printed kinds, sales brochures, flyers, company cards, and bulk postcard mailings. However, because of the static nature of litho printing, it is not perfect for variable print pieces that will certainly be mailed to individual receivers such as statements, letters, and personalized postcards.

The 30-Second Trick For 24??media

The most recent developments in print technology are assisting to bring numerous of offset's advantages into the digital printing world absolutely altering the face of modern printing! There are some essential differences in between Offset Printing and Digital Printing (Window Vinyl). This overview shows the advantages and downsides of each printing method. There is an undeniable and expanding number of advantages to using the electronic print procedure.

Today's electronic print tools is among the most advanced on the marketplace. Below are a few of the greatest advantages of using electronic printing: control the digital print area, with full-color printing completed in one procedure and seamlessly published directly from a print data. Without a prolonged set up procedure, the calibration time of a details task is reduced, adding to quicker print time and overall distribution.

The inkjet printing process has actually aided to change the sector in addition to the high quality and rate of the outcome. The current inkjet innovation can publish on standard offset supplies with plain, silk, and glossy surfaces. High-grade digital print coupled with software-managed shade management techniques adds maximum value to publish items and makes production processes a lot more dependable than countered.

24??media Things To Know Before You Get This

(https://filesharingtalk.com/members/610008-za24media?tab=aboutme&simple=1)

Exact amounts of ink and printer toner are used to prevent waste. Environment-friendly and naturally degradable inks and toners are also offered for even more lasting printing. Digital print additionally gets rid of the requirement to wash plates or coverings with harmful chemicals at the end of the printing procedure. As the quality of electronic print solutions boosts, the advantages come to be significantly apparent and beneficial.

Variable data aids services reach their specific customers and audience with uniquely-created and customized content. As modern technology improves, the link top quality of digital printing has actually come to be second-to-none, with higher detail, color match capabilities and total accuracy. Without the need to wash plates or use excess ink, electronic printing is also less inefficient and usually more eco-friendly.

Conventional printing approaches, such as offset lithography ("balanced out") and flexography ("flexo"), involve several make-ready actions to move an original photo to a substratum. These approaches call for the production of a series of plates mounted on a cyndrical tube to transfer ink that forms the wanted picture when integrated on paperboard and various other packaging products. Stickers.

Things about 24??media

Digital printing, with less moving pieces, is more agile than offset in this regard.

It's a means to blend your packaging and advertising and marketing techniques. Decreased set-up time saves cash on the front end. And considering that these are not huge bulk orders, smaller businesses can manage to print without having to meet the greater and a lot more pricey print thresholds of typical printing. Digital printing aids shield your brand name against counterfeiting by integrating obvious and concealed options on your product packaging.

Be certain you team up with a printing and product packaging partner that has the appropriate accreditations. While eleventh-hour printing and customization are a big advantage, electronic may not constantly be the most effective approach for you. For instance, counter printing has the benefit of cost-effectiveness with big print runs, particularly those with sophisticated ornamental effects and specialty finishes.

Everything about 24??media

The positive plate, with its smooth surface area, attracts oil-based inks and drives away water. In contrast, the unfavorable plate, with its rough texture, soaks up water and pushes back oil. Rubber rollers are after that utilized to move the photo from the plate to the corrugated surface area.

Corrugated paper can sometimes show to be a tough surface area to print on, yet Litho prints to a separate surface area and is then laminated flooring to it, making it easy to print high-grade pictures. It can be incredibly consistent, even for lengthy runs. In truth, the extra you publish, the less costly the prices become for Litho.

What Litho doesn't offer you is exactly what Digital does, customization. Expensive set up Longer turnaround No Variable Data Printing Smaller sized color range, shades can be less bright Digital printing is the procedure of printing digital pictures straight onto the corrugated substrate making use of a single-pass, direct-to-corrugate technique.

Report this page